We wanted to develop a particular resonator with a 5 axes pantograph exaggerating the depth of a classical violin.

After many manual trials we have decided to create an harmonic resonator drawing in 3d a light form that would have been too hard to prepare with the same precision by hand.

We have worked on many different forms to understand ho to push over the usual dimensions of a violin.

We have developed an handle where we can install different kinds of resonators.

Thanks to 3d cad we could exercise our fantasy and explore new possibilities.

To develop the initial form we have used different softwares

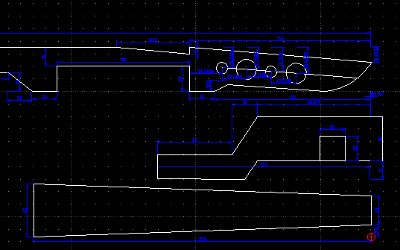

For the production of handles we have initially drawn 2d masks for cutting the wood boards. 2d Masks.

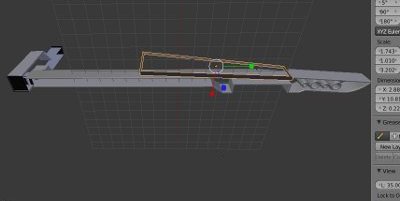

From the 2d masks we have extruded the borders to create the first version of a violin moving all the parts in the 3d space. Extrusion

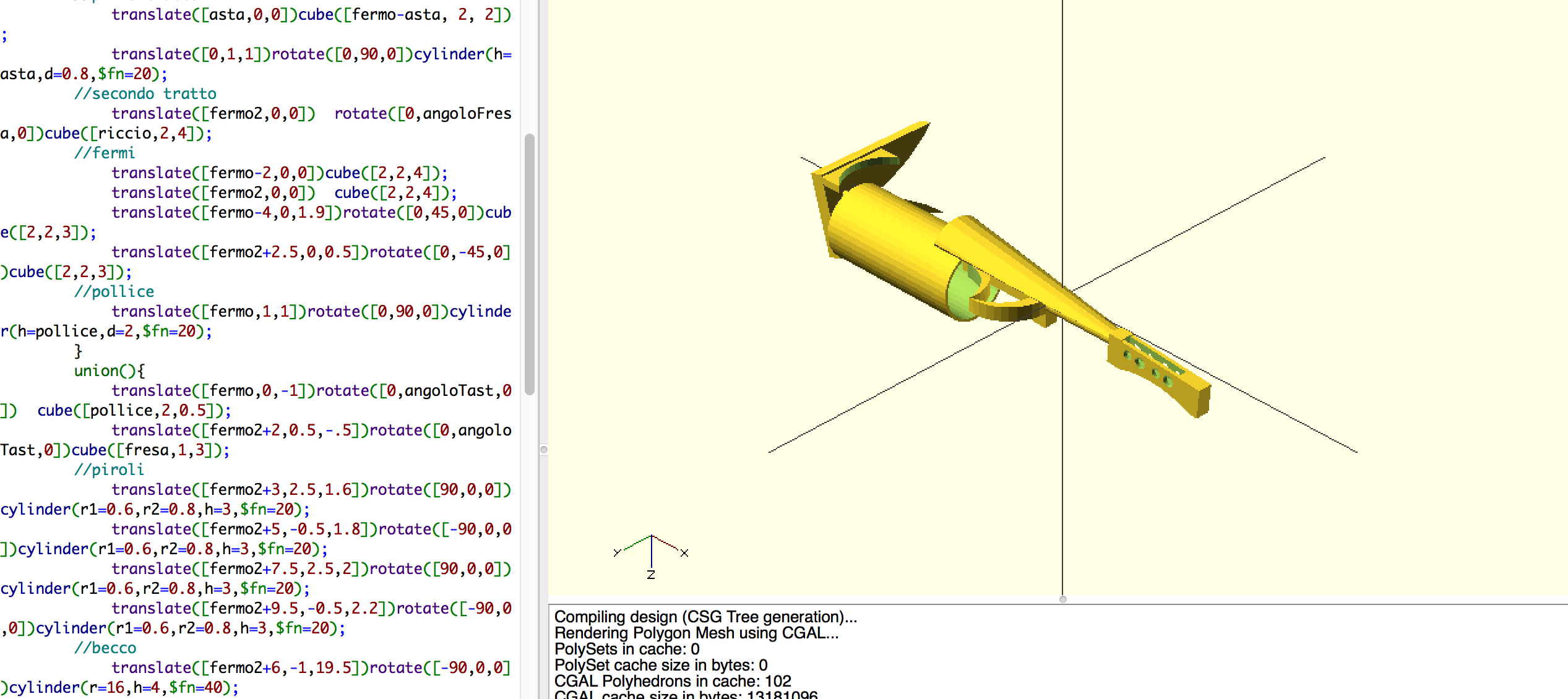

We have created the complete form of the violin modeling all the parts with the parametrization script of openScad. We have created the solids with difference and unions using a sort of virtual thorne to cut out the space for the pins. 3d complete.

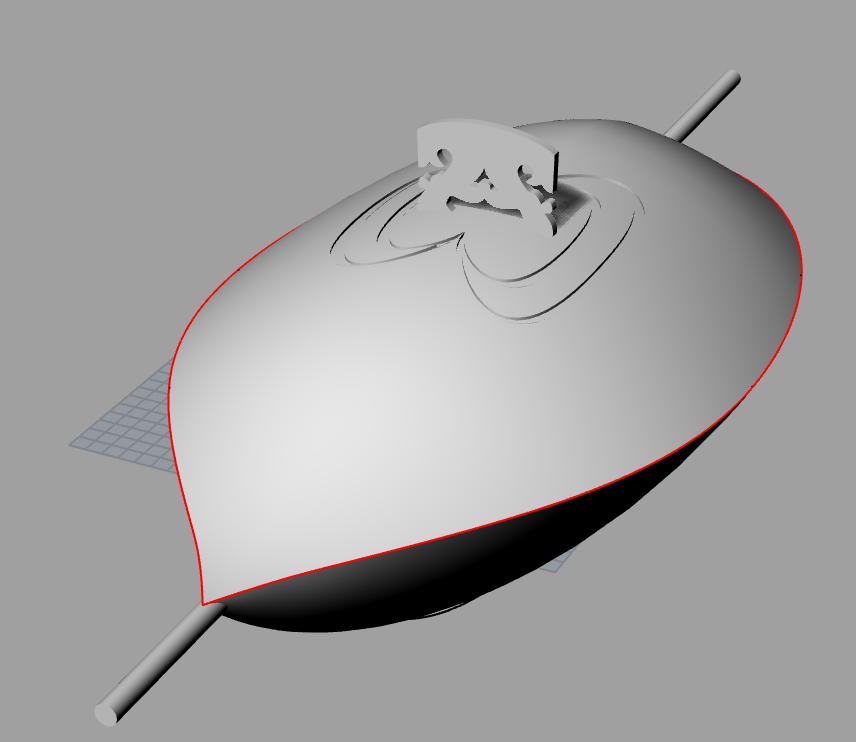

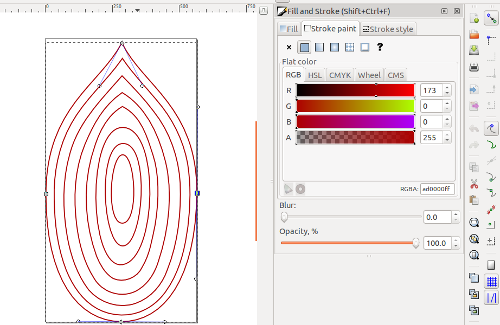

To draw the border of the harmonic resonator we have created isolines with Bezier. The form has been drawn on the right side and mirrored on the other side. 2d Border.

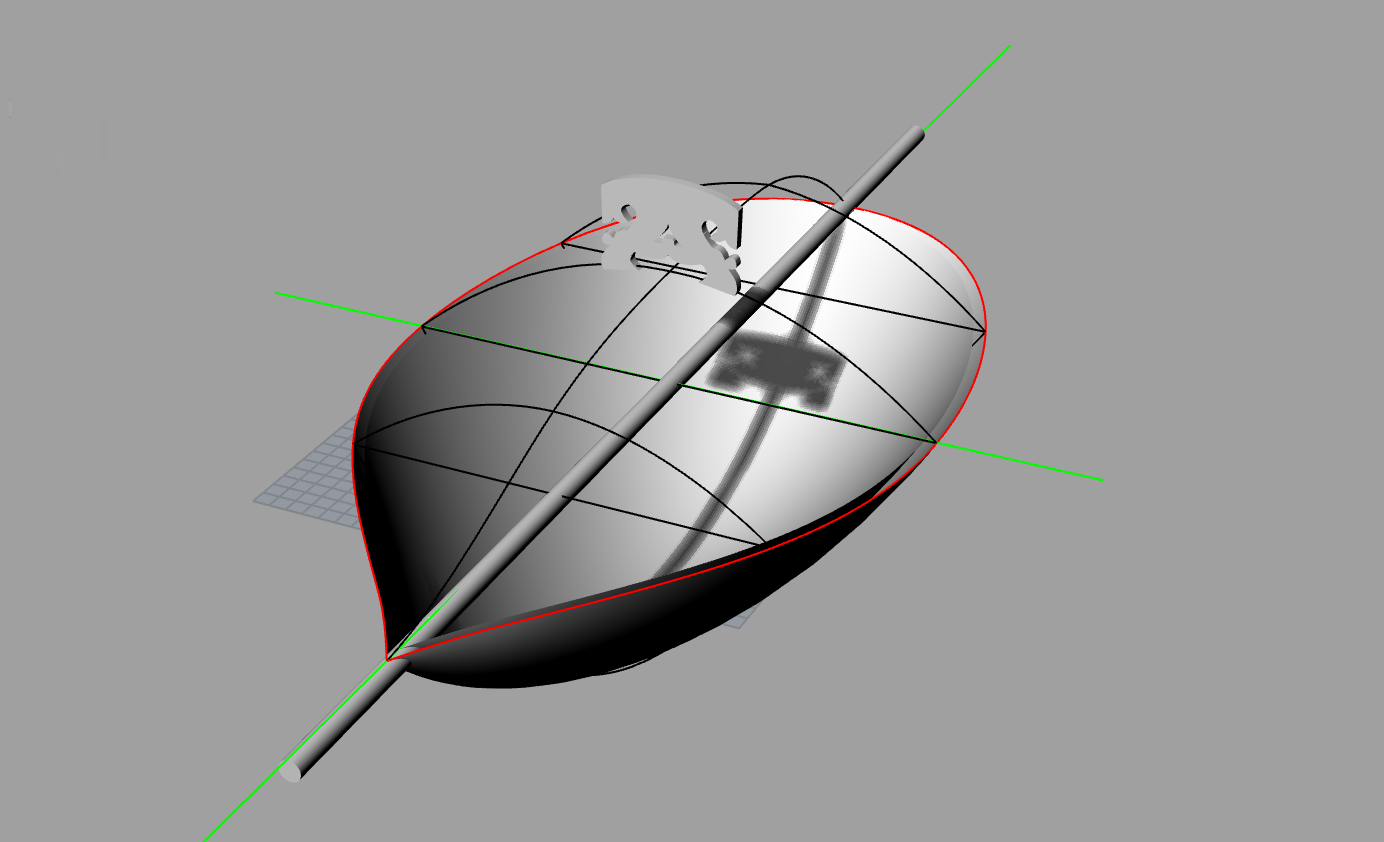

To create the volume we have tried different commands in rhino. At the end we have obtained the best result creating parallel lines between the border and the normal plane. We have created the surface with "Surface from network of curves". We have then create an "offest" of the surface towards the inner part and given a volume of both parts. Upper part, Lower part .

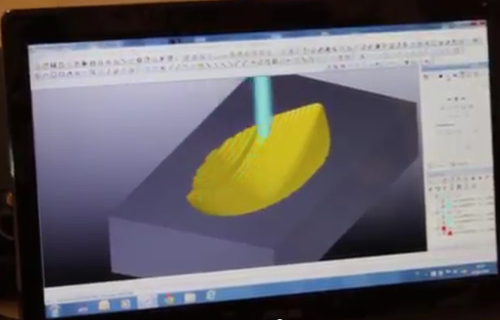

The final part is the CAM programming to translate the 3d form into machine instructions for the 5 axis pantograph. CAM

The harmonic resonator have than been printed, glued, varnished and installed on a "ad hoc" created handle.